Unlock Precision and Efficiency with FlexiCoat

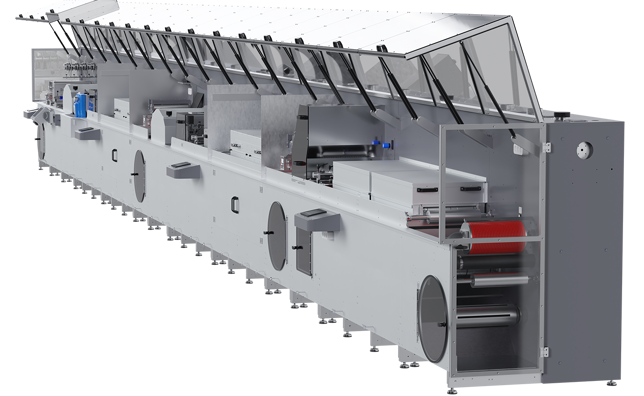

FlexiCoat revolutionizes coating operations, delivering unparalleled precision and efficiency. Our cutting-edge digital control system gives you complete control over crucial coating parameters, such as web speed, web tension, temperatures, and ink delivery parameters. This guarantees consistent and uniform coatings across various functional materials, ultimately reducing material waste, and setup times, and achieving exceptional coating quality effortlessly.

Explore our Modular Design for Versatility

FlexiCoat's modular design offers unmatched versatility, allowing you to customize the machine to match your unique production requirements. Whether you're dealing with conductive inks, adhesives, or photoactive materials, our interchangeable coating and curing modules make it easy to adapt to different materials and processes. This flexibility empowers you to discover new applications and expand your product range.

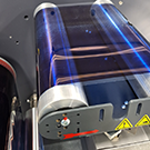

Discover Laser Patterning and Inspection System

Enhance your capabilities with precise and customizable material patterning using laser technology. Our optional integrated inspection system ensures rigorous quality control, detecting defects and maintaining consistent product quality throughout the production process.

Seamless Digital Connectivity and Smart Automation

Embrace the principles of Industry 4.0 with FlexiCoat's digital connectivity and intelligent automation features. Effortlessly integrate our machine into your existing production line and harness real-time data for process optimization. The intuitive user interface ensures straightforward operation and monitoring, while remote access and diagnostics enhance maintenance efficiency. Experience the transformative power of digital technology with FlexiCoat.

Exceptional Support and Expertise

Selecting FlexiCoat means partnering with a trusted ally dedicated to your success. Our team of experts provides comprehensive training, ongoing support, and maintenance services to guarantee smooth operation and maximize uptime. We are committed to your satisfaction and stand ready to provide prompt assistance whenever you need it.

Embrace the Future of Coating with FlexiCoat

Don't miss out on the opportunity to revolutionize your functional materials production. Embrace the future of coating technology with FlexiCoat's modular and fully digital roll-to-roll slot-die coating machine.

|

Precision Control with FlexiCoat FlexiCoat offers precise digital control, OPC UA data export, a versatile modular platform, and seamless upgradability with additional modules. |

|

|

Versatile Applications with FlexiCoat Discover the endless possibilities of FlexiCoat, serving applications like photovoltaics, battery coatings, sensors, and fuel cell membranes. |

|

|

Coating Flexibility FlexiCoat is your versatile choice, operating as both an R&D system and a production machine, bridging the gap between lab and factory applications. |

|

|

Multi-Functional Features FlexiCoat boasts automated slot-die coating with a heated roller, along with optional inline screen printing, busbar application, and inspection systems. |

|

| SPECIFICATIONS | METRIC | IMPERIAL |

|---|---|---|

| Web width | 330 mm | 13” |

| Coating width | 300 mm | 11.8” |

| Speed | 0 - 30 m/min | 0 - 98.4 ft/min |

| Rewind diameter | Up to 800 mm | 31.5” |

| Core diameter | 50 - 150 mm | 2 - 6” |

| Weight per module (approx.) | 400 kg | 881.8 Ibs |

| Module Dimensions | ||

| W x D x H | 1,0/ 2,0 x 1,5 x 2,0 m | 3.2/ 6.5 x 4.9 x 6.5 ft |

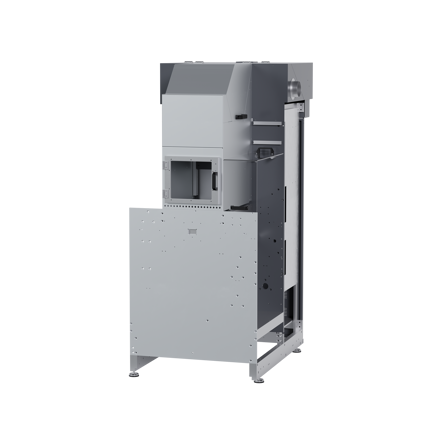

The Unwind Module

Unwind Module with optional web guide, vacuum NIP, and web-cleaner. Touch and non-touch.

The Stacked Curing Module

Stacked curing section with a maximum of 7.2m curing total. A combination of hot-air and optional IR or UV combinations are available.

The Flat Curing Module

Flat curing section with 2 individual zones of hot-air curing.

The Preparation Module

Preparation module with many options to prepare your web fx: inkjet, bus-bar applicator, and corona.

The Rewind Module

Module for rewinding with NIP for tension control and space for inspection- or similar equipment.

The Screen Print + Slot-die Module

Combination coating module for a multi-pass process for reuse of curing section. Here shown with rotary screen and slot-die.

The Spray Coating Module

Module for spray coating.

The Slot-die + IR Module

Combined coating and curing module with slot-die station and NIR curing for immediate curing at specific IR wavelength with temperature control.

The UV Curing Module

Module for intense UV curing at specific wavelengths and temperature control.

The Slot-die Module

Automized, digital slot-die station with motorized vertical, cross-web, and tilt movements. Optional integrated ink supply system.

The Laser Module

The laser module for layer patterning or cutting. Configurable with either: CO2, nano-, femto- or picosecond laser source.

The Intermediate Winder Module

The intermediate winder module with NIP for long production lines allows section-by-section use and proper web control.

Try out our 3D FlexiCoat configurator and customize your functional materials line according to your specific preferences and needs.

09 September 2024

26 June 2024

30 May 2024

30 May 2024

30 May 2024

30 May 2024

02 August 2023

09 August 2023

08 February 2023

We encourage you to reach out to us with any questions, feedback, or requests you may have. Our team is dedicated to providing you with the best possible service and support. We look forward to hearing from you and building a lasting partnership.

Thank you for considering GM Functionals as your partner in functional materials. Your inquiries are important to us, and we will respond promptly to assist you in every way possible.

Contact us at:

Email: sales@gm.dk

Phone: +45 4581 2300