The printed electronics industry has experienced remarkable growth, providing flexible and cost-effective electronic devices. This expansion can be attributed to the crucial roles played by coating and roll-to-roll production, which enable efficient and scalable manufacturing.

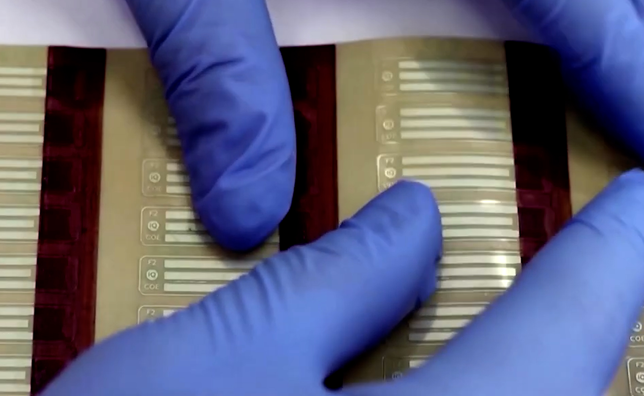

Coating stands as a fundamental process in printed electronics. It involves the precise deposition of inks onto flexible substrates to create electronic components. Meanwhile, roll-to-roll production, a continuous and integral method, ensures the seamless movement of substrates through various stages, including coating, drying, and curing. This process guarantees high-speed, high-volume production, resulting in enhanced efficiency and reduced manufacturing costs.

Roll-to-roll production is a game-changer in the world of electronics manufacturing. Its continuous and adaptable process allows for swift parameter adjustments, making it ideal for quick transitions between various designs, a critical feature in industries like wearable technology and IoT devices, where customization is paramount.

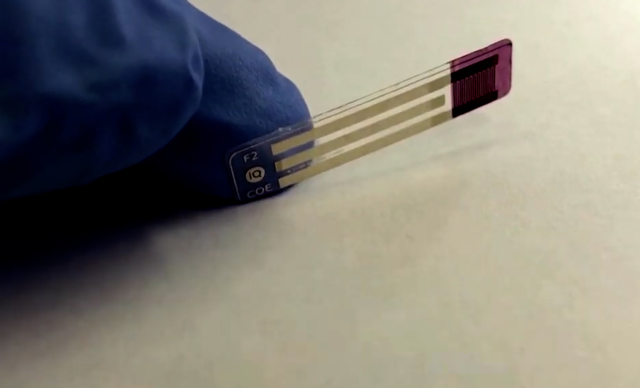

Within the domain of printed electronics, the adoption of roll-to-roll coating has marked the beginning of a transformative era for flexible and lightweight device technology. By utilizing substrates such as plastic films, manufacturers can create bendable electronic components. This innovation has paved the way for the integration of electronics into curved surfaces, giving rise to flexible displays, sensors, wearable devices, and portable gadgets.

23 August 2023