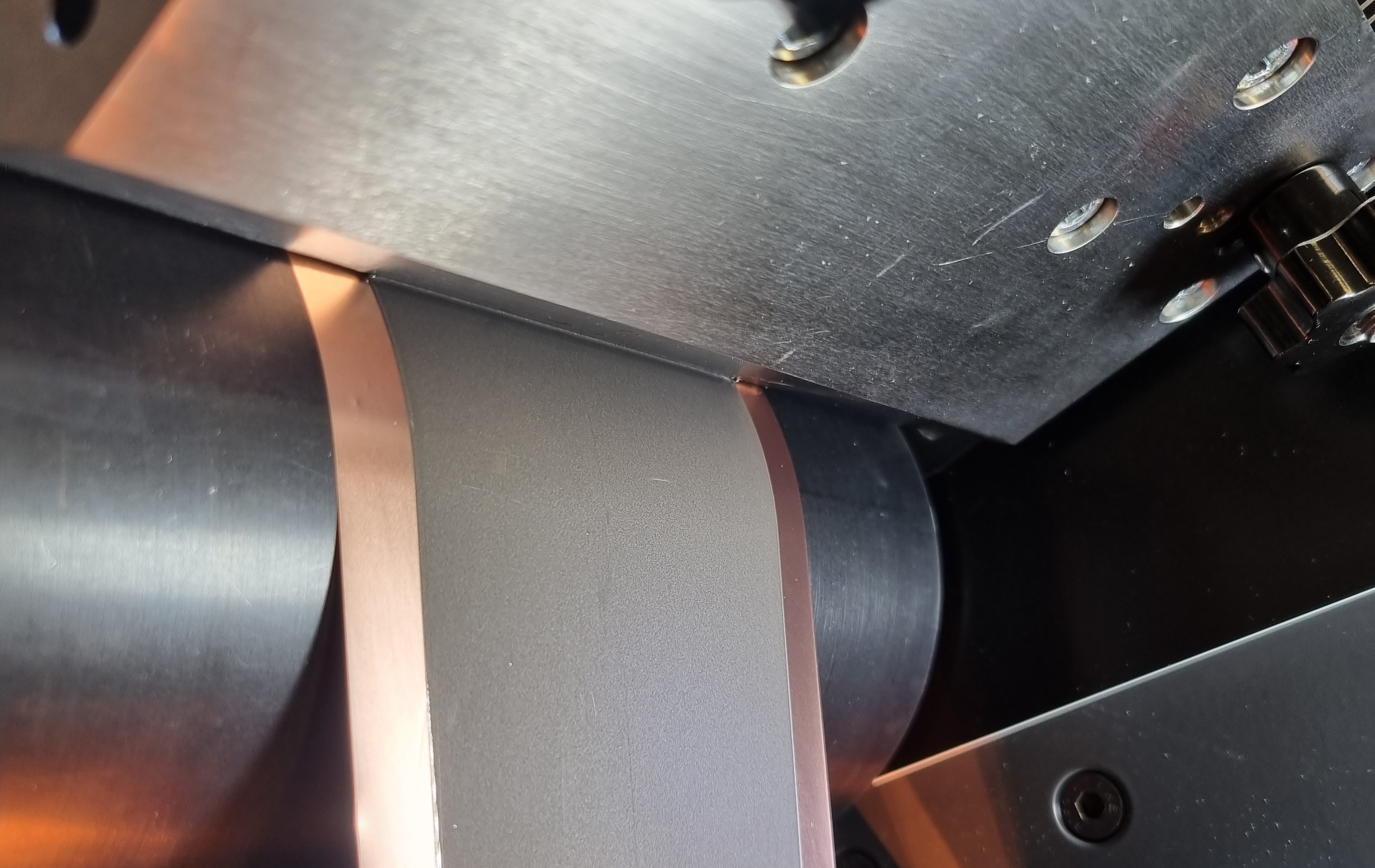

Battery R2R

Roll-to-roll production of slot-die coated lithium-ion battery cells faces several challenges that need to be addressed for successful implementation. Let's explore some of the key challenges associated with roll-to-roll production of slot-die coated lithium-ion battery cells:

1. Coating Thickness Uniformity: Achieving precise and uniform coating thickness across large-scale roll-to-roll production is a critical challenge. Consistent and uniform coating thickness is essential for maintaining the desired performance characteristics of the lithium-ion battery cells. Variations in coating thickness can impact cell performance, energy density, and overall battery performance. Accurate control of coating parameters, such as viscosity, flow rate, and drying conditions, is crucial to ensuring uniformity throughout the entire roll-to-roll production process.

2. Electrode Material Compatibility: Slot die coating processes often involve the deposition of multiple layers, including active materials, binders, conductive additives, and current collectors. Ensuring compatibility between these materials is essential for optimal electrode performance. Compatibility issues can arise due to differences in solvents, rheology, and drying conditions. Addressing these compatibility challenges is crucial to prevent delamination, cracking, and other issues that may compromise the performance and reliability of the battery cells.

3. Drying and Curing Processes: Efficient and effective drying and curing of coated electrode materials pose challenges in roll-to-roll production. Proper drying and curing processes are crucial to achieve desired electrode properties, adhesion, and structural integrity. Achieving uniform drying across the entire web while maintaining high production speeds is a significant challenge. It requires optimizing drying parameters, such as temperature, humidity, and airflow, to ensure complete solvent evaporation and adequate curing of the coated electrode layers.

4. Quality Control and Defect Detection: Implementing reliable quality control measures is vital for roll-to-roll production of slot-die coated lithium-ion battery cells. Detecting defects such as pinholes, cracks, or coating inconsistencies in real-time is critical to ensure the production of high-quality cells. The use of advanced inspection techniques, such as inline imaging or spectroscopy, can aid in identifying defects and enable prompt corrective actions during the manufacturing process.

5. Material and Process Compatibility: Lithium-ion battery technology continues to evolve, with advancements in electrode materials, binders, electrolytes, and cell designs. Implementing these advancements in roll-to-roll production requires ensuring material and process compatibility. Changes in materials or processes may impact coating properties, drying kinetics, or overall cell performance. It is crucial to evaluate the compatibility of new materials and processes with slot-die coating and roll-to-roll production techniques to maintain high-quality and high-performance battery cells.

6. Scalability and Cost Efficiency: Scaling up roll-to-roll production while maintaining high performance and cost efficiency is a key challenge. As production volumes increase, optimizing material utilization, minimizing waste, and reducing production costs become paramount. Efficient use of materials, optimization of coating and drying parameters, and streamlining production processes are crucial for achieving scalability and cost competitiveness.

Addressing these challenges requires collaboration between battery researchers, material scientists, engineers, and manufacturers. Ongoing research and development efforts are focused on improving coating uniformity, drying and curing processes, quality control methods, and material compatibility. Overcoming these challenges will be instrumental in unlocking the full potential of roll-to-roll production for slot-die coated lithium-ion battery cells, enabling the mass production of high-performance and cost-effective energy storage solutions.