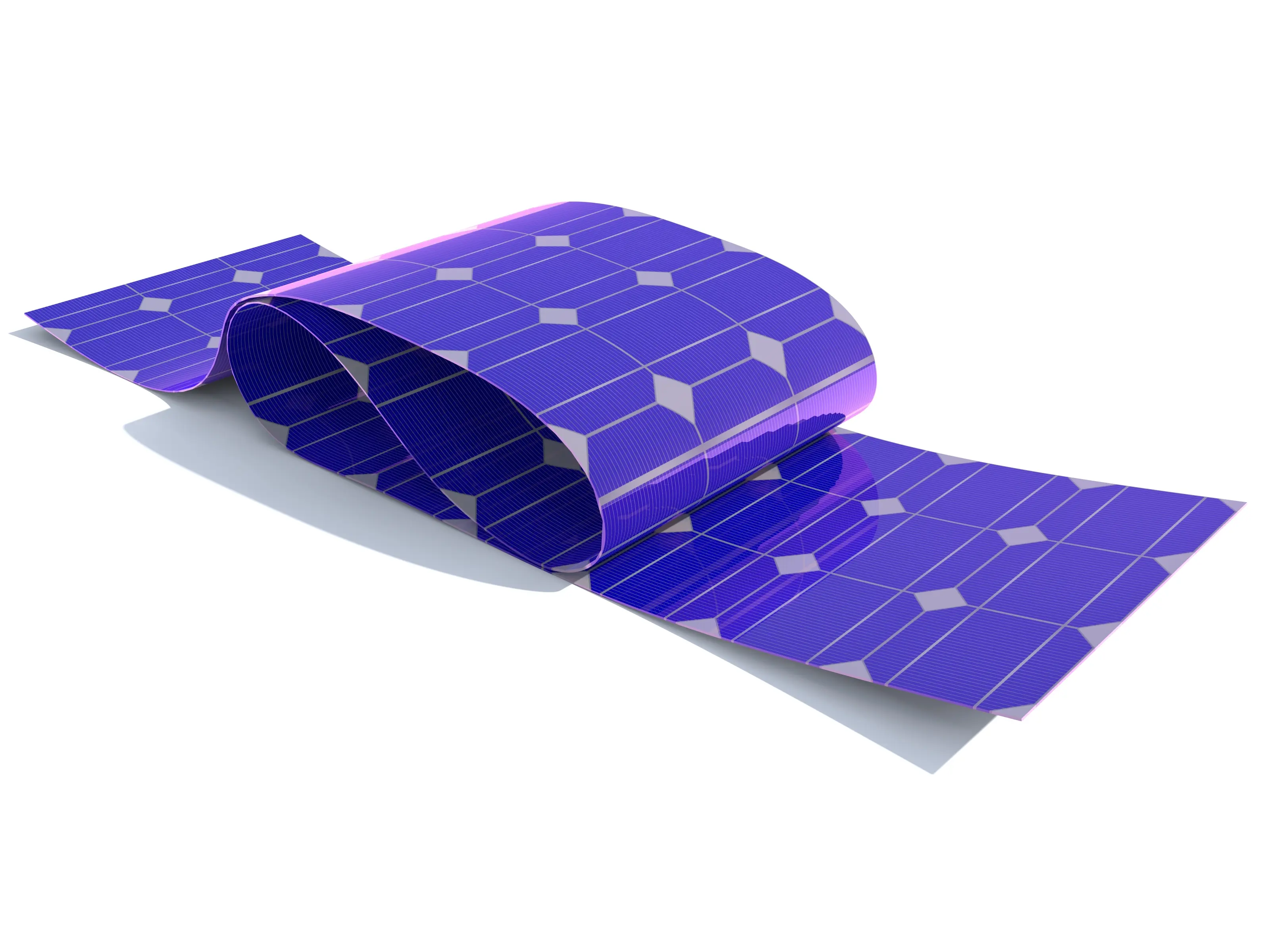

OPV Stack

Roll-to-roll production techniques are well-suited for manufacturing OPV cells due to their ability to deposit thin films continuously on flexible substrates. Here's a description of each layer in an OPV stack and its potential roll-to-roll application:

1. Substrate: Similar to perovskite solar cells, the substrate provides mechanical support and can be a flexible material like plastic or metal foil. Roll-to-roll production enables the continuous deposition of the substrate material on a large-scale roll, facilitating the fabrication of flexible OPV cells.

2. Transparent Conductive Oxide (TCO) Electrode: The TCO layer, typically made of materials like indium tin oxide (ITO) or zinc oxide (ZnO), serves as a transparent electrode that allows light to pass through and collects the generated charges. Roll-to-roll techniques such as sputtering, chemical vapor deposition, or solution-based methods like inkjet printing can be used to deposit a uniform and conductive TCO layer on the substrate.

3. Hole Transport Layer (HTL): The HTL layer facilitates the selective extraction and transport of holes (positive charges) generated by the absorption of light. Materials like PEDOT:PSS (poly(3,4-ethylenedioxythiophene): polystyrene sulfonate) or small molecule-based HTLs are commonly used. Roll-to-roll methods like slot-die coating, spin coating, or screen printing can be employed to deposit a uniform HTL layer on the TCO electrode.

4. Active Layer: The active layer, also known as the photoactive layer, consists of a blend of conjugated polymer or small molecule electron donor material and an electron acceptor material. This layer absorbs photons from sunlight, creating electron-hole pairs. Roll-to-roll techniques like blade coating, slot-die coating, or spray coating can be adapted to deposit a continuous and uniform active layer on top of the HTL.

5. Electron Transport Layer (ETL): The ETL facilitates the extraction and transport of electrons (negative charges) generated by the absorption of light in the active layer. Materials like fullerene derivatives (e.g., PCBM) or non-fullerene acceptors are commonly used as ETL materials. Roll-to-roll methods such as slot-die coating, spray coating, or inkjet printing can be utilized to deposit a uniform ETL layer on top of the active layer.

6. Metal Electrode: The metal electrode layer collects the electrons generated in the active layer and completes the electrical circuit. Materials like aluminum or silver can be used for the metal electrode. Roll-to-roll techniques like thermal evaporation, sputtering, or printing methods can be employed to deposit a thin metal electrode layer on top of the ETL.

Roll-to-roll production allows for the continuous and scalable fabrication of OPV cells by depositing each layer on flexible substrates. Techniques such as slot-die coating, spray coating, inkjet printing, blade coating, screen printing, or thermal evaporation are compatible with roll-to-roll processes and can be adapted for each layer of the OPV stack. These methods ensure uniformity, high throughput, and precise control over layer thickness, making roll-to-roll production an attractive option for large-scale manufacturing of organic photovoltaic cells.