Perovskite Solar Cells

Roll-to-roll production of perovskite solar cells faces several challenges that need to be addressed for successful implementation. Let's explore some of the key challenges associated with roll-to-roll production of perovskite solar cells:

1. Stability and Durability: Perovskite solar cells are known for their excellent efficiency, but their long-term stability and durability pose challenges. The perovskite material is sensitive to moisture, oxygen, and light, which can degrade the cell's performance over time. Developing encapsulation techniques and barrier materials that effectively protect the perovskite layers from environmental factors is crucial for ensuring the long-term stability of roll-to-roll produced cells.

2. Uniformity and Reproducibility: Achieving uniformity and reproducibility across large-scale roll-to-roll production is a challenge. Controlling and maintaining consistent deposition of perovskite layers, as well as other layers such as electron and hole transport materials, is critical for achieving high-performance solar cells. Variations in coating thickness, composition, and interface quality can impact the device's efficiency and reliability.

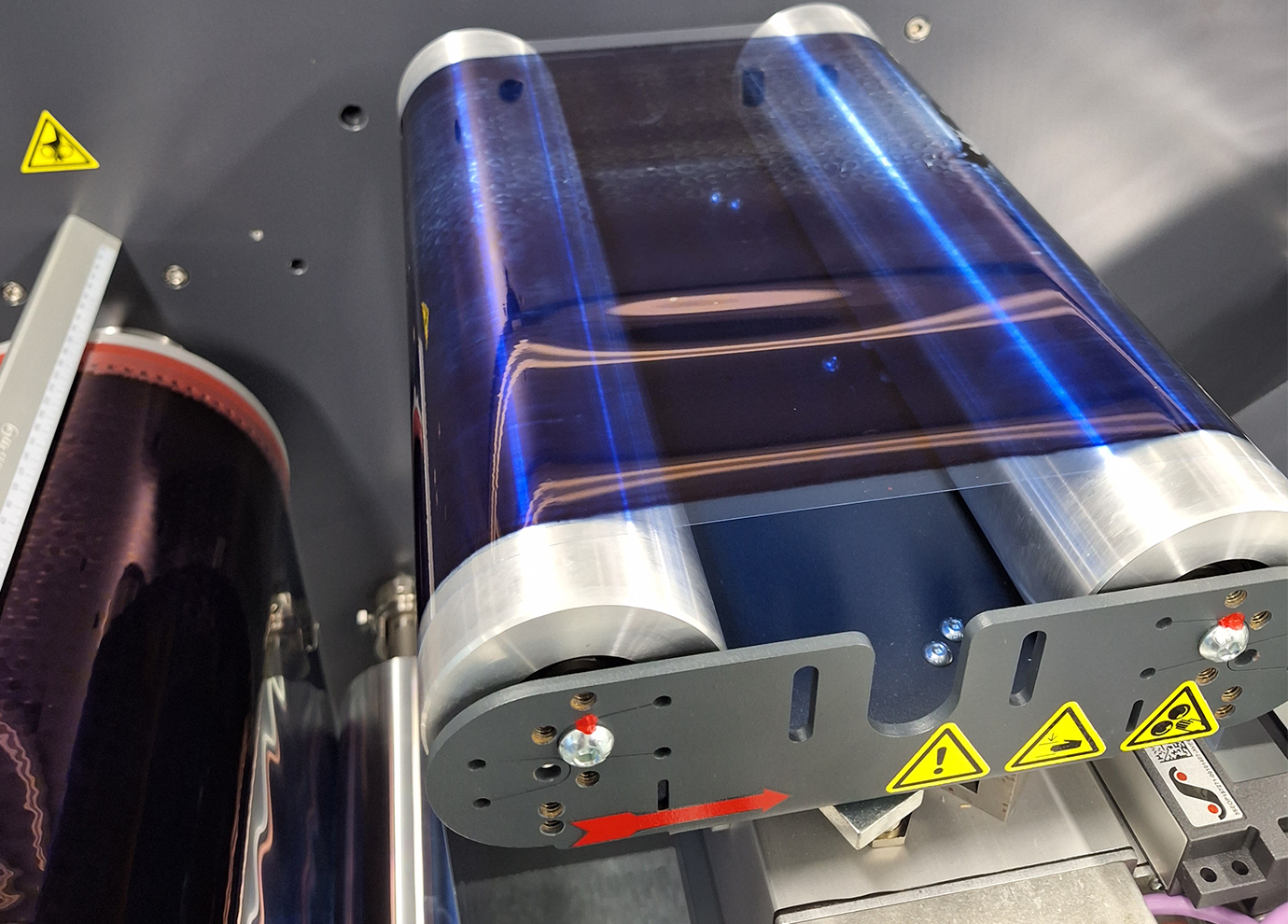

3. Scalability of Manufacturing Processes: Scaling up roll-to-roll production while maintaining the same performance characteristics as small-scale lab-scale devices is a significant challenge. Translating laboratory-scale processes to large-scale manufacturing requires addressing issues such as efficient ink formulation, coating speed optimization, and ensuring reliable and continuous operation of the roll-to-roll equipment.

4. Cost Reduction: Perovskite solar cells have the potential for low-cost production, but achieving cost competitiveness with traditional photovoltaic technologies is a challenge. This includes optimizing the use of materials, developing efficient manufacturing processes, and minimizing waste and production losses. Additionally, the choice of materials and their availability, as well as the development of cost-effective encapsulation techniques, play a crucial role in cost reduction.

5. Upscaling Device Manufacturing: Integrating the roll-to-roll production of perovskite solar cells into existing manufacturing infrastructures can be challenging. Adaptation and integration of the roll-to-roll coating equipment, as well as the development of quality control measures, are necessary for ensuring consistent and high-quality production on a large scale.

Addressing these challenges requires collaborative efforts from researchers, material scientists, engineers, and manufacturers. Ongoing research and development efforts are focused on improving the stability, scalability, reproducibility, and cost-effectiveness of roll-to-roll production of perovskite solar cells. Overcoming these challenges will be instrumental in unlocking the full potential of perovskite solar cells for renewable energy generation.