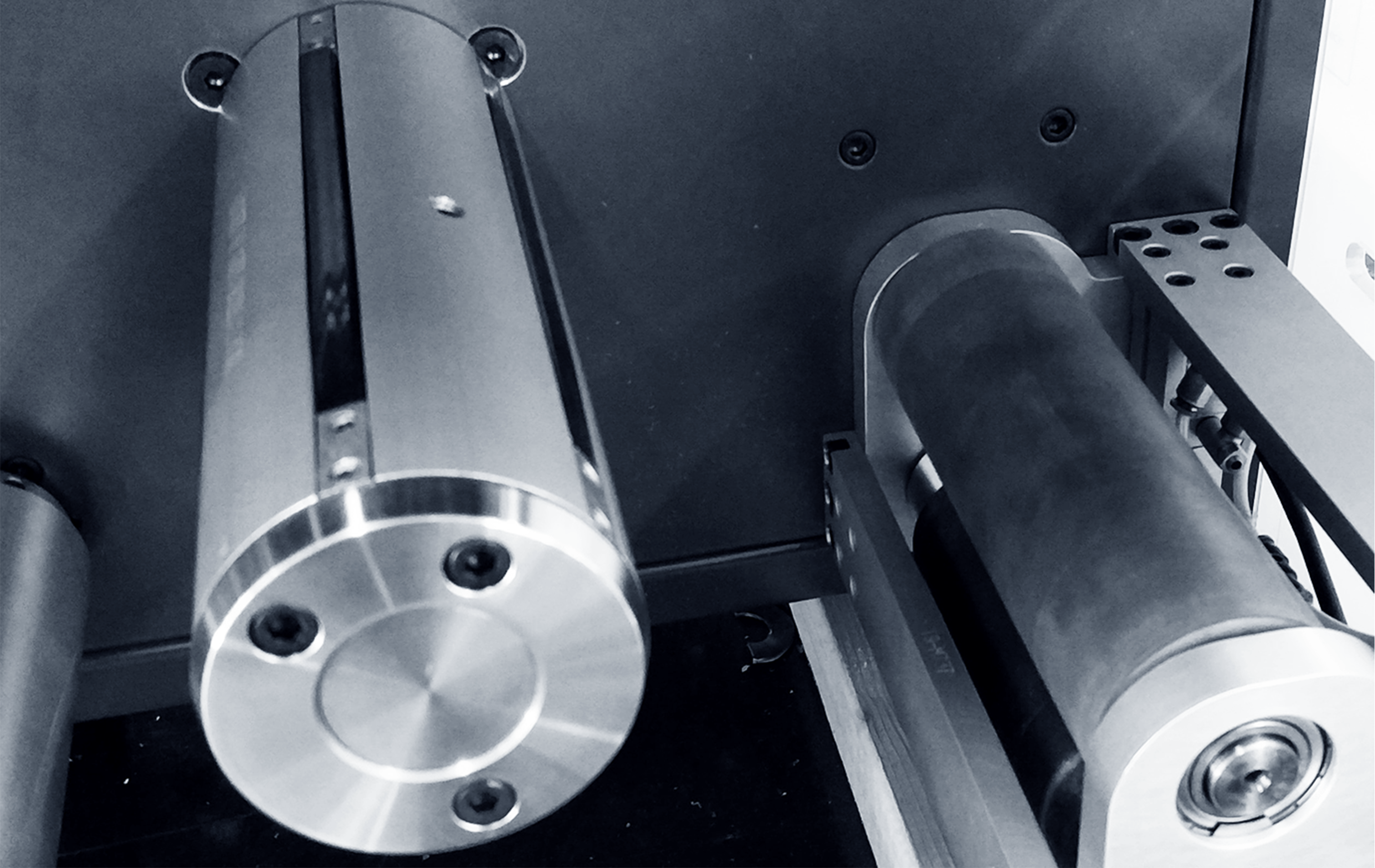

Roll-to -roll inspection machines

Roll-to-roll (R2R) inspection machines play a vital role in ensuring the quality and consistency of functional materials during high-volume manufacturing processes. Here are some of the most common uses of R2R inspection machines for functional materials:

Coating Quality Control: R2R inspection machines are frequently used to assess the quality of thin coatings on flexible substrates. They ensure uniform coating thickness, detect defects like pinholes, inhomogeneities, and inconsistencies, and monitor coating adhesion. This is essential in various industries, including printed electronics, photovoltaics, and battery manufacturing. These machines can identify and flag defects, such as scratches, damages, or contamination on the surface of materials. For example, in printed electronics, R2R inspection machines help detect defects that can compromise the functionality of electronic circuits. R2R inspection machines minimize material waste by identifying defects early in the manufacturing process. This is crucial for cost-effective production and environmental sustainability, especially in industries like photovoltaics and display manufacturing.

Application examples

Printed Electronics: In the production of printed electronics, R2R inspection machines ensure the integrity of printed circuits by detecting errors like missing conductive lines, misalignment, and short circuits. This quality control is crucial for the reliability of electronic devices.

Solar Cell Manufacturing: In photovoltaic manufacturing, R2R inspection machines verify the quality of solar cell coatings and ensure that they are defect-free. This is essential for the efficiency and longevity of solar panels.

Barrier Film Inspection: R2R inspection is used to assess the quality of barrier films, which are essential in applications like flexible OLED displays and organic electronics. Detecting defects in these films ensures the protection and longevity of electronic components.

Quality Assurance in Battery Production: R2R inspection machines are employed to validate the quality of battery components, such as anode and cathode coatings. They help ensure that these components meet performance and safety standards.

Automated Process Control: R2R inspection machines are often integrated into production lines to provide real-time quality control. They can automatically trigger adjustments in the manufacturing process based on inspection results, helping maintain product consistency and reduce waste. R2R inspection machines are versatile tools that are widely used in various industries to maintain the quality, consistency, and efficiency of manufacturing processes for functional materials. They are critical in detecting defects, ensuring uniformity, reducing waste, and ultimately delivering high-quality end products in industries ranging from electronics to textiles and beyond. With an inspection line from GM Functionals, you can achieve a higher quality and process feedback in your process.