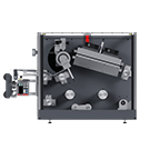

Compact and Versatile Design for Research Labs:

TestCoat's compact table-top design is an ideal solution for research laboratories with limited space. Despite its size, TestCoat offers uncompromised functionality. It features a single slot-die station, making it easy to coat various functional materials on flexible substrates. The integrated infrared curing section ensures swift and efficient drying, reducing processing time and boosting throughput.

Unparalleled Precision and Control:

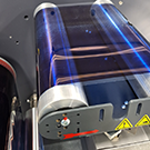

TestCoat provides researchers with exceptional control over the coating process. With precise adjustments for coating thickness, speed, and other essential parameters, you can achieve uniform coatings for a wide range of functional materials. This precision guarantees accurate and reproducible results, enhancing the reliability of your research findings.

Expand Research Possibilities:

TestCoat's versatility opens up new research possibilities. With its slot-die station, you can explore a wide array of functional materials, including conductive inks, adhesives, coatings, and more. The infrared curing section ensures efficient and controlled drying, supporting various coating processes. TestCoat empowers you to conduct comprehensive experiments and investigate different material formulations and coating parameters.

Expert Support and Guidance:

At GM, we recognize the significance of comprehensive support for researchers. Our dedicated team of experts is committed to providing the guidance and assistance required to maximize TestCoat's potential. We offer comprehensive training, ongoing technical support, and maintenance services to ensure peak performance and minimize downtime. Your success remains our top priority.

Experience the Power of TestCoat:

Overcome space constraints and unleash the full potential of your research with TestCoat, the compact table-top roll-to-roll slot-die coating machine designed for functional materials research. Elevate precision, accelerate experiments, and broaden your research horizons. Contact us today to discover more about TestCoat and elevate your research to new heights.

|

Compact Size The TestCoat boasts a compact design with a 15cm web width and 60x60cm cabinet size, ideal for tabletop placement and glovebox integration. |

|

|

Slot-die Coating Experience high-precision slot-die coating featuring vertical and cross-web adjustments for exceptional control. |

|

|

Precise Curing Benefit from integrated IR curing with precise temperature control and regulation for optimal results. |

|

|

Roll-to-Roll or Loop Functions Choose between two web functions: roll-to-roll or loop, expanding flexibility in your coating process. |

|

09 September 2024

22 August 2023

| Specifications | Metric | Imperial |

|---|---|---|

| Web width | 50 - 150 mm | 0.4 - 5.9” |

| Substrate | 50 - 200 µm | 2 - 8 pt. |

| Max. unwind | 240 mm | 9.5” |

| Unwind core diameter | 76,2 or 152,4 mm | 3 or 6” |

| Max. rewind | 240 mm | 9.5” |

| Rewind core diameter | 76,2 or 152,4 mm | 3 or 6” |

| Power/ Air | 240V + N + PE, 16A, 6 bar | |

| Dimensions (W x D x H) | 1,1 x 0,7 x 0,7 mm |

We encourage you to reach out to us with any questions, feedback, or requests you may have. Our team is dedicated to providing you with the best possible service and support. We look forward to hearing from you and building a lasting partnership.

Thank you for considering GM Functionals as your partner in functional materials. Your inquiries are important to us, and we will respond promptly to assist you in every way possible.

Contact us at:

Email: sales@gm.dk

Phone: +45 4581 2300