The lithium-ion battery industry has experienced remarkable growth and innovation recently, responding to the surging demand for energy storage solutions in portable electronics, electric vehicles, and renewable energy systems. In this context, the pivotal roles of coating and roll-to-roll production techniques cannot be overstated, as they enable the efficient and scalable production of lithium-ion batteries.

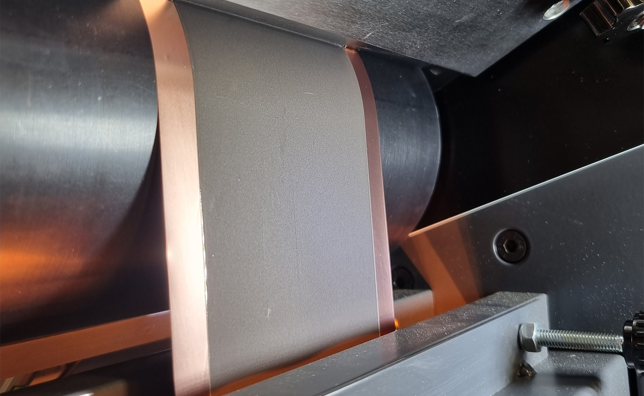

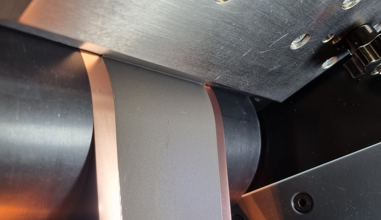

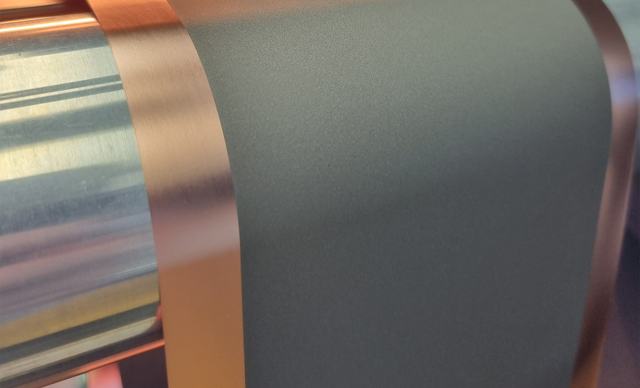

Coating is vital in lithium-ion battery production, depositing materials for electrode layers. Roll-to-roll, or continuous manufacturing, enhances efficiency with uninterrupted processing of flexible substrates, like metal foil, through coating, drying, and curing stages. This boosts production speed, volume, and efficiency, reducing costs.

In the realm of lithium-ion battery manufacturing, the use of roll-to-roll production is a game-changer. This method simplifies and streamlines various manufacturing steps, consolidating them into a single production line. This not only reduces the need for extensive handling but also minimizes contamination risks, ultimately enhancing overall efficiency. Roll-to-roll production seamlessly incorporates functional layers such as binders and electrolytes, making workflows more straightforward.

A standout feature is its adaptability, facilitating quick transitions between materials and designs for various battery types and sizes. In the evolving lithium-ion battery market, adaptability is invaluable for competitiveness and meeting diverse demands.