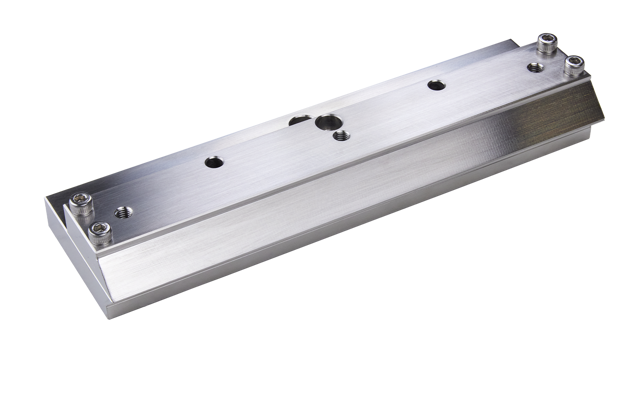

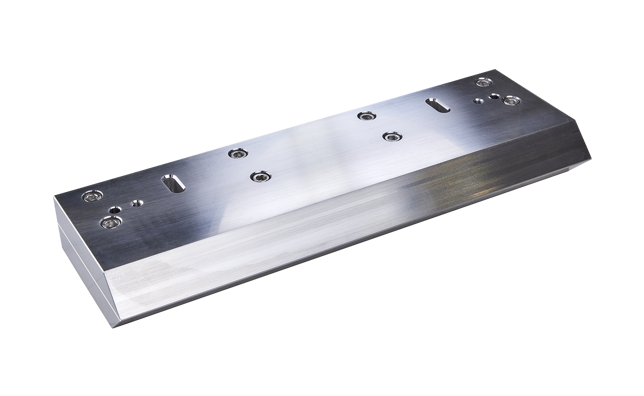

Slot-die coating is a sophisticated and highly precise technique used to apply uniform thin films to a variety of substrates. At the heart of this technology is the slot-die head, a critical component that determines the flow and deposition of the coating material. Slot-die heads are versatile tools used across numerous industries, from electronics to pharmaceuticals, due to their ability to produce consistent and high-quality coatings.

Precision and Control

Uniform Coatings: Slot-die heads are designed to deliver coatings with exceptional uniformity and thickness control. This precision is vital for applications that require consistent layer properties.

Adjustable Parameters: Operators can fine-tune coating thickness and uniformity by adjusting the flow rate of the coating material, the speed of the substrate, and the gap between the slot-die head and the substrate.

Versatility

Wide Range of Coating Materials: Slot-die heads can handle a diverse array of materials, including polymers, organic semiconductors, nanoparticle suspensions, and conductive inks. This versatility makes them suitable for various industrial applications.

Substrate Compatibility: They can be used to coat different types of substrates such as glass, metal foils, plastics, and flexible films, enhancing their applicability across multiple sectors.

Applications of Slot-Die Heads

Electronics Manufacturing

Thin-Film Transistors and Displays: Slot-die heads are crucial in the production of thin-film transistors, OLED displays, and other electronic components where uniform coatings are essential for device performance.

Printed Electronics: Used in the fabrication of printed circuit boards, sensors, and other electronic devices, where precise layer thickness is critical for functionality.

Renewable Energy

Solar Cells: Slot-die coating is widely used in the production of photovoltaic cells, ensuring uniform layers that enhance the efficiency and longevity of solar panels.

Batteries and Fuel Cells: Essential for the application of electrode materials and separators, contributing to the performance and reliability of energy storage and conversion devices.

Advantages of Slot-Die Heads

Efficiency and Cost-Effectiveness

Reduced Material Waste: The precise control over the coating process minimizes material waste, making slot-die coating a cost-effective method compared to other techniques like spray or dip coating.

High Throughput: Slot-die heads can be used for both small-scale and large-scale production, offering scalability for industrial applications.

Versatility in Applications

The 50 mm width is suitable for research and development purposes where small-scale testing and optimization of coating processes are essential before scaling up to larger production lines.

Used extensively in the production of printed electronics, such as thin-film transistors, sensors, and photovoltaic cells, where precise layer thickness and uniformity are critical for device performance.

Employed in the coating of medical devices and components, ensuring biocompatible materials are applied uniformly, enhancing the performance and safety of the devices.

Efficiency and Scalability

The precision of the slot-die coating process reduces material waste compared to other methods like spray or dip coating, leading to cost savings.

The 150 mm slot-die head is ideal for both mid-scale production and can be scaled up for larger production lines by using multiple heads or wider slot-die systems.

Industrial and Large-Scale Applications

The 300 mm width is ideal for large-scale industrial production, enabling high throughput and efficiency in manufacturing processes.

Widely used in the production of large-area electronics, such as displays, touch screens, and OLED panels, where uniform coatings are essential for performance and visual quality.

Critical in the fabrication of large-area photovoltaic cells, batteries, and fuel cells, where consistent coating quality impacts the efficiency and longevity of the devices.

30 May 2024

30 May 2024

30 May 2024

30 May 2024

15 April 2024

15 April 2024

15 April 2024

We encourage you to reach out to us with any questions, feedback, or requests you may have. Our team is dedicated to providing you with the best possible service and support. We look forward to hearing from you and building a lasting partnership.

Thank you for considering GM Functionals as your partner in functional materials. Your inquiries are important to us, and we will respond promptly to assist you in every way possible.

Contact us at:

Email: sales@gm.dk

Phone: +45 4581 2300